Construction of the Insight Race Car

In the beginning ...

Little is known about the early life of

2000 Honda

Insight #358. What is known is that it was a 5 speed manual

transmission model in classic Silverstone Metallic. It probably lived

somewhere

near Plainfield, NJ. Sometime in 2002 it met with an immovable object.

Its left front side was crushed destroying the headlight, front bumper

and fenders, breaking the windshield, bending the

drivers side door slightly, and deploying the airbags. #358 was

pronounced totaled and sent to the salvage yard. It was saved from

aluminum recycling by Inline Pro later in 2002. The car then sat in

Inline's

shop waiting to begin its new life.

Highland Racing took control of the car in September 2003.

Chassis

The car was first

striped of all parts down to the frame. All that

was left was the front suspension, steering mechanism, rear suspension,

windows, and doors/hatch. Everything else (interior panels, wiring,

brake lines, etc.) was removed. The suspension was left in for ease of

transport and the windows so that Lexan molds could be made.

The car was first

striped of all parts down to the frame. All that

was left was the front suspension, steering mechanism, rear suspension,

windows, and doors/hatch. Everything else (interior panels, wiring,

brake lines, etc.) was removed. The suspension was left in for ease of

transport and the windows so that Lexan molds could be made.

Then it was off to Ken Keir Race cars for some serious work.

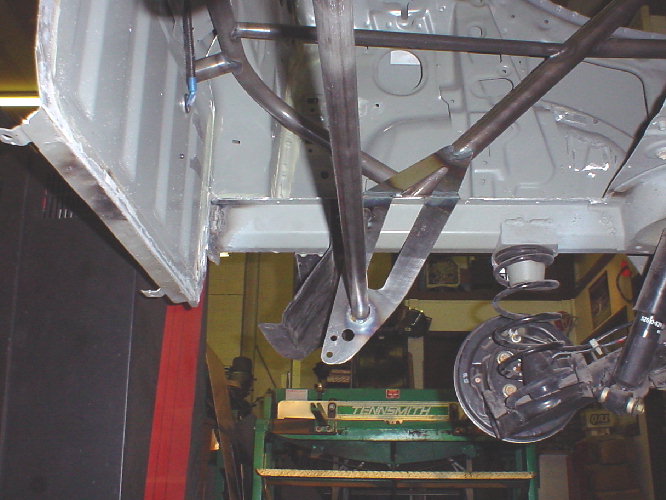

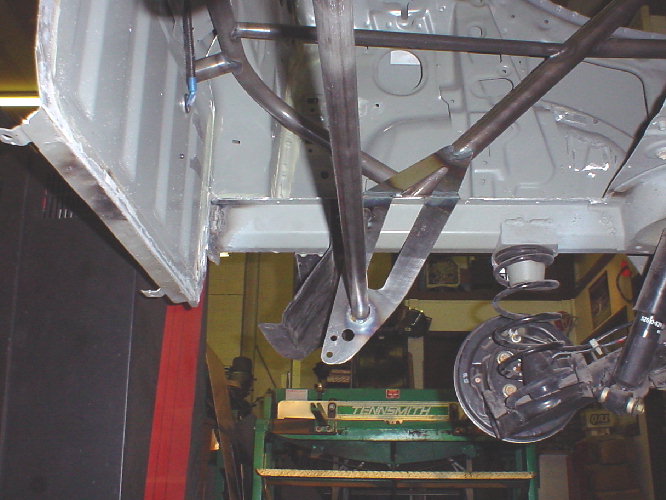

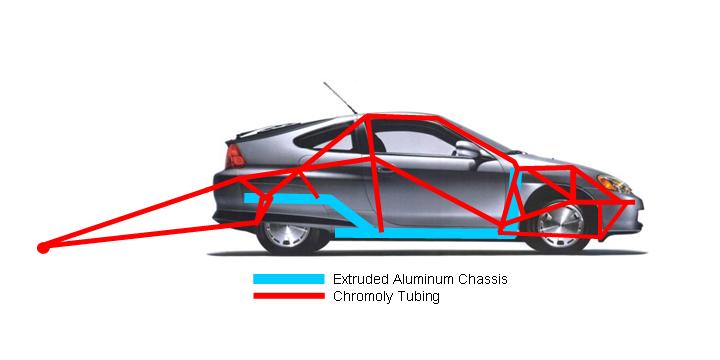

A full 6 point roll

cage was constructed out of

chromoly tubing. The all aluminum chassis of the Insight meant that

each point had to be bolted to the floor using plates per NHRA safety

regulations. As part of this, a Jazz

race seat was installed as well as a steering column and window net

supports.

A full 6 point roll

cage was constructed out of

chromoly tubing. The all aluminum chassis of the Insight meant that

each point had to be bolted to the floor using plates per NHRA safety

regulations. As part of this, a Jazz

race seat was installed as well as a steering column and window net

supports.

The front bumper and fenders were replaced with a one piece carbon

fiber front end to improve

aerodynamics, reduce weight and simplify maintenance. All other

exterior body

panels are stock Insight aluminum and plastic components

including the aerodynamic rear fender skirts.

A flat, NHRA spec Pro Stock style spoiler was built and attached to the rear hatch.

The interior was striped of all accessories, electrical lines, sound deadening and any flanges and attachment points that were not needed. The base interior was left in the original Sliverstone Metallic color with large holes covered in aluminum sheet. The silver background is accented by the lightweight carbon fiber sandwich panels on the doors and sides along with a custom carbon fiber dashboard. The role cage and all tubing was painted in hammered black to further complement the aluminum and carbon fiber interior scheme.

Chassis

The car was first

striped of all parts down to the frame. All that

was left was the front suspension, steering mechanism, rear suspension,

windows, and doors/hatch. Everything else (interior panels, wiring,

brake lines, etc.) was removed. The suspension was left in for ease of

transport and the windows so that Lexan molds could be made.

The car was first

striped of all parts down to the frame. All that

was left was the front suspension, steering mechanism, rear suspension,

windows, and doors/hatch. Everything else (interior panels, wiring,

brake lines, etc.) was removed. The suspension was left in for ease of

transport and the windows so that Lexan molds could be made.Then it was off to Ken Keir Race cars for some serious work.

A full 6 point roll

cage was constructed out of

chromoly tubing. The all aluminum chassis of the Insight meant that

each point had to be bolted to the floor using plates per NHRA safety

regulations. As part of this, a Jazz

race seat was installed as well as a steering column and window net

supports.

A full 6 point roll

cage was constructed out of

chromoly tubing. The all aluminum chassis of the Insight meant that

each point had to be bolted to the floor using plates per NHRA safety

regulations. As part of this, a Jazz

race seat was installed as well as a steering column and window net

supports.

The rear of the roll cage was reinforced

to support the wheelie bars

which attach just below the hatch and under the car. The wheelie bars

are adjustable height and extend approximately 60" from the rear

bumper.

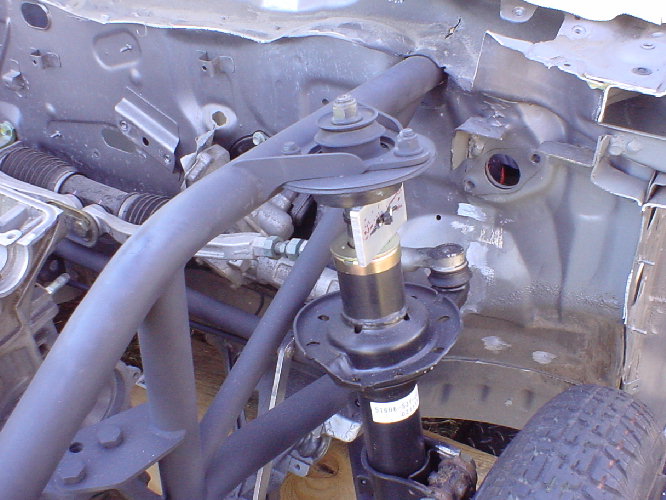

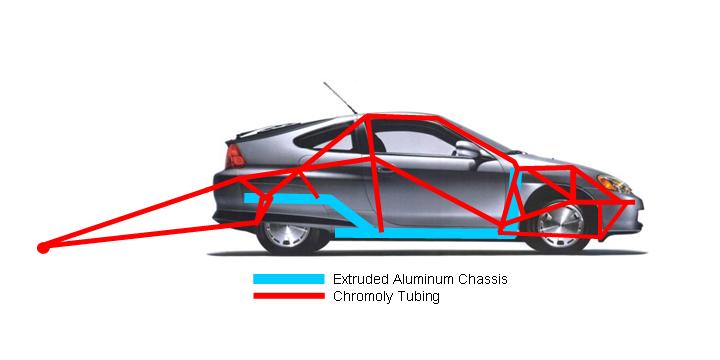

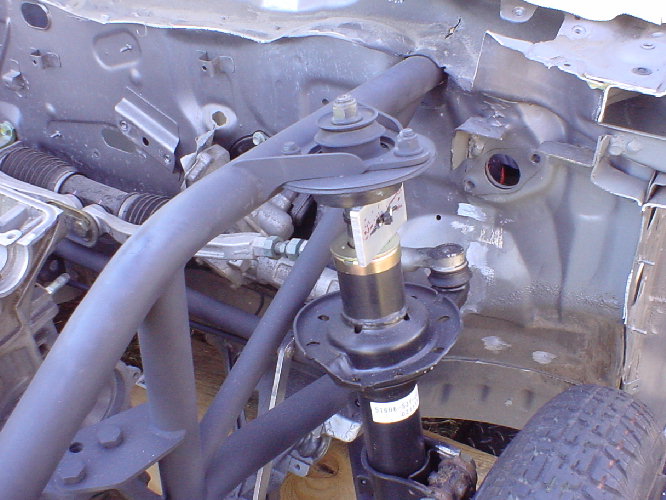

The front frame rails on the Insight are

composed of hexagonal aluminum extrusions with improper geometry and

insufficient strength

for a 300 HP B or K series motor. Similarly, the Insight's MacPherson

strut front suspension utilizes an aluminum spindle and

lower control arms to reduce weight. These will also not withstand the

stress of drag racing. As a result, the entire front end frame was

replaced to provide the proper strength and support.

After the original front frame components of the Insight were removed, a new frame structure was made from chromoly tubing. The tubing extends from the roll cage forward providing mounting for the motor and an anchor for the shock towers. The engine was attached to these using custom fabricated aluminum plates. This allows a B series motor to be attached at all five attachment points for strength and stability. The frame system was intentionally made symmetrical so that it could be modified for a K series motor in the future.

After the original front frame components of the Insight were removed, a new frame structure was made from chromoly tubing. The tubing extends from the roll cage forward providing mounting for the motor and an anchor for the shock towers. The engine was attached to these using custom fabricated aluminum plates. This allows a B series motor to be attached at all five attachment points for strength and stability. The frame system was intentionally made symmetrical so that it could be modified for a K series motor in the future.

To beef up the suspension, the Insight's

aluminum spindles will be

replaced with steel units

from a late model Civic. While still a MacPherson strut suspension

system, the Civic's slight differences in geometry require some custom

modification of the struts. The Insight's aluminum lower control arms

were replaced with chromoly

units fabricated by Ken Keir. These utilize the same mounting points as

the original but with much stronger components. The modified original

struts are retained along with

the steering mechanism (minus the electrical power assist). Further

suspension stability is provided by front mounted traction bars

connected to the frame. The springs

were replaced with harder and shorter springs to get

approximately a 3" drop from stock ride height.

The stock trailing arm rear suspension

was retained largely intact.

The lower bump stop was modified and the springs replaced to allow

approximately 3" lower ride. Shocks were replaced with adjustable

racing shocks.

The resulting frame structure works with

the original aluminum

substructure to

provide safety, light weight and a stiff racing chassis that will

support the

loads of hard launches and high horsepower motors.

Body

The stock glass windows were removed and

replaced with light weight

Lexan. The side windows are reasonably flat and use flat Lexan sheets

mounded to the original window frames. The front and rear windows have

compound curves and had to be custom molded for the proper fit and

aerodynamics. The doors were gutted leaving only the outer skin, the

window frames, door latches and a minimum amount of inner shell for

rigidity. As most parts of the doors are aluminum or plastic, the

striped door with Lexan windows weighs only 22lb each. The rear hatch

was also gutted to provide a frame for mounting the Lexan window. The

complex electro-mechanical rear hatch latch mechanism was replaced with

a simpler system to provide a light weight working hatch.

A flat, NHRA spec Pro Stock style spoiler was built and attached to the rear hatch.

The interior was striped of all accessories, electrical lines, sound deadening and any flanges and attachment points that were not needed. The base interior was left in the original Sliverstone Metallic color with large holes covered in aluminum sheet. The silver background is accented by the lightweight carbon fiber sandwich panels on the doors and sides along with a custom carbon fiber dashboard. The role cage and all tubing was painted in hammered black to further complement the aluminum and carbon fiber interior scheme.